LOW VISIBILITY + STRUCK-BY HAZARDS

PROTECT YOUR CREW FROM ONE OF OSHA'S "FATAL FOUR" BY FINDING THE RIGHT HI-VIS FOR THE JOB.

THE COST OF LOW LIGHT + STRUCK-BY ACCIDENTS

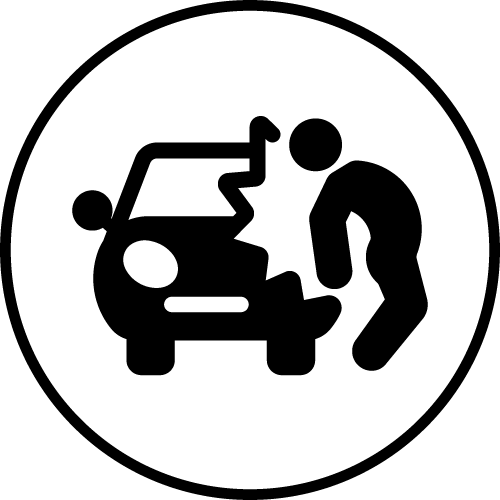

The most common visibility-related hazards are pedestrian vehicle incidents and struck-by objects/equipment, with more struck-by vehicle deaths involving construction workers than any other occupation (1 in 4).

PEDESTRIAN-VEHICLE INCIDENTS

6,110 injuries

6,110 injuries 330 deaths

330 deaths $659,200,200*

$659,200,200*

STRUCK-BY OBJECTS & EQUIPMENT

196,140 injuries

196,140 injuries 716 deaths

716 deaths $9,111,400,000*

$9,111,400,000*

Source: 2020 BLS / NSC: *$1.22M per death + $42K per injury

WHAT WORKERS ARE MOST AT RISK FOR STRUCK-BY ACCIDENTS?

Where there’s high activity, there’s struck-by risk—but especially in industries involving heavy machinery (75% of fatalities involve equipment such as trucks or cranes).

What can you do to keep your crew safe?

Of course you know hi-vis is key to preventing low-light/struck-by accidents (in addition to engineering and administrative controls like traffic control planning and designated safe zones for heavy equipment).

But do you know what hi-vis is right for the job according to ANSI/ISEA 107-2020 (a.k.a. the hi-vis standard)? Gold star if you do. If not, scroll on and you'll be an expert in no time.

THE STANDARD

THE WHAT, WHEN, WHERE AND WHY

Hi-vis is a workwear staple but, with annual fatalities nearing the thousands, compliance is about more than just looking the part.

ANSI/ISEA 107-2020: THE HI-VIS STANDARD

ANSI/ISEA 107-2020 is the industry regulation that sets design requirements and performance testing criteria for all types and classes of high-visibility wear, particularly the amount of required fluorescent background material and reflective to keep workers safe and seen.

Background Color

Purpose

Enhances daytime visibility by adding contrast against background environment

Approved FLUORESCENT Colors

Reflective Material

Purpose

Enhances low-light nighttime visibility by reflecting light back towards the original source

Approved Reflective

Design

Purpose

Creates biomotion that signals awareness to the brain that it is looking at a living, breathing thing

Requirements

ANSI/ISEA 107-2020 HI-VIS TYPES & PERFORMANCE CLASSES

To meet ANSI/ISEA 107-2020, every high visibility garment requires both a type and a class. Here’s how to decode it.

ANSI/ISEA 107-2020: TYPES

Type O

When it's used

For off-road, indoors or controlled environments, parking lots, festivals, extracting/refining oil &gas, warehouse/factories

Applications

Compatible with

Type R

When it's used

For environments with moving traffic or equipment traffic. Minimum level of protection for workers exposed to roadway rights-or-way and temporary traffic control (TIC) zones

Applications

Compatible with

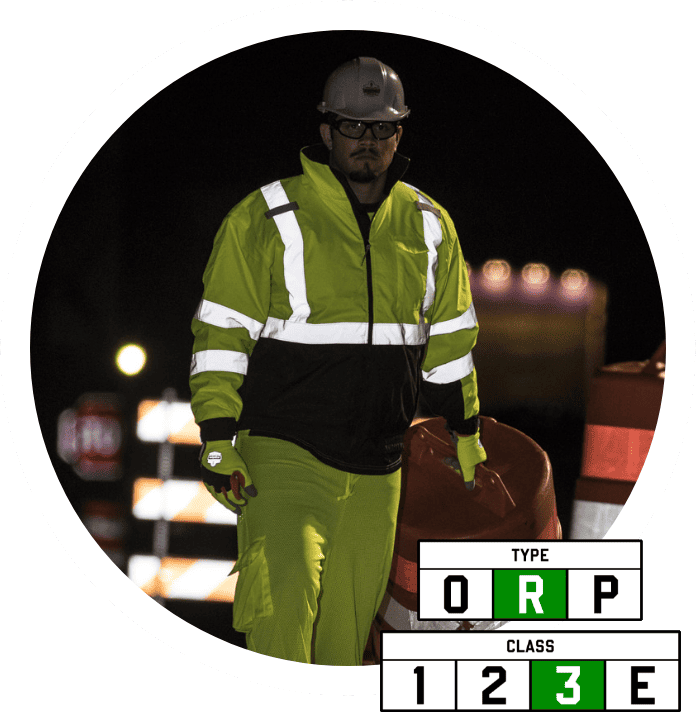

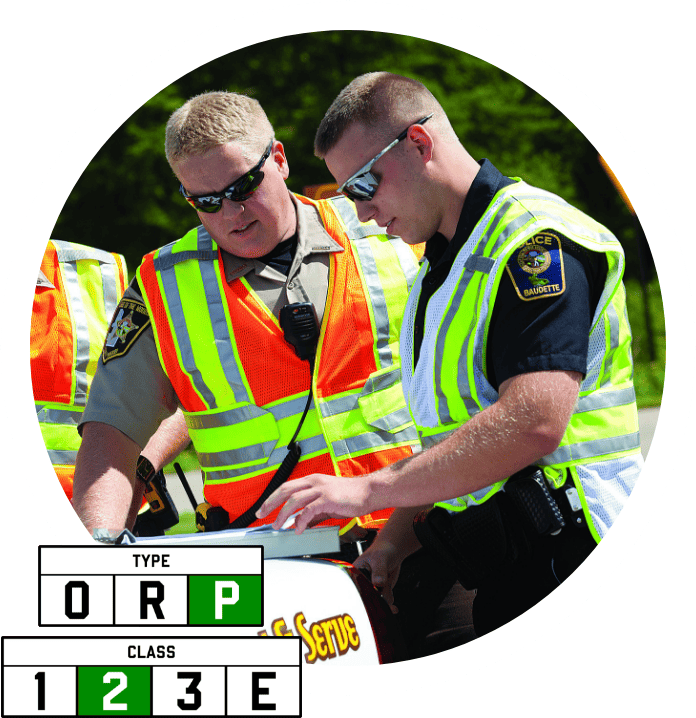

Type P

When it's used

For environments with moving traffic or equipment traffic, emergency/incident response, police, fire, EMS only

Applications

Compatible with

ANSI/ISEA 107-2020: Classes

Class 1

WHAT IT IS

Minimum hi-vis materials needed to differentiate wearer

Visibility

MINIMAL

HIGHEST

Requirements

Class 2

WHAT IT IS

Additional hi-vis materials for better definition of the human form (a.k.a., biomotion)

Visibility

MINIMAL

HIGHEST

Requirements

Class 3

WHAT IT IS

Most hi-vis materials for best definition of the human form in complex backgrounds

Visibility

MINIMAL

HIGHEST

Requirements

Class E

WHAT IT IS

Garments that do not classify when worn alone, but achieve Class 3 when worn with other Class 2 or Class 3 garment

Visibility

MINIMAL

HIGHEST

Requirements

Service Life

WHEN TO REPLACE HI-VIS CLOTHING

Jobsite wear and tear is inevitable. Recognizing your gear’s service life is critical to staying safe.

Retire your hi-vis if the fabric or reflective is…

Torn/cracked

Heavily soiled

Faded or dull

Burned or otherwise damaged

No longer comfortable

*Psst.. make sure to cut it in half so it can no longer be worn by anyone.

Gear guide

SO… WHAT HI-VIS DOES YOUR CREW NEED?

Now that you’ve got the basics down, cross your types and dot your classes to find the right wear for your worksite.

Type O, Class 1

Off-road protection

Minimum amounts of protection suitable for off-road, indoors or controlled environments such as parking lots

Type O, Class 1 Hi-Vis

TYPE R, CLASS 2

ROADWAY

The baseline for protection in construction and transportation, with increased fluorescent background and additional retroreflective to ensure visibility around moving vehicle and equipment traffic

TYPE R, CLASS 2 HI-VIS

TYPE R, CLASS 3

ROADWAY

The greatest amount of protection most suitable for busy roadways, construction and transportation zones with the most biomotion and reflectivity

TYPE R, CLASS 3 HI-VIS

Type P, Class 2

Public safety

Specifically for emergecy/incident response, police, fire and EMS working in environments with moving traffic or equipment traffic

TYPE P, CLASS 2 HI-VIS

CLASS E (SUPPLEMENTAL)

Class E + class 2 = class 3

Pants, shorts and other gear that do not meet standards on their own but, when combined with Class 2 or Class 3 garments, achieve Class 3 classification

CLASS E HI-VIS

Make sure the gear you have is the gear you need

When in doubt, check the tag

In addition, any high visibility apparel manufacturer worth their weight in reflective tape should be able to provide you with a Declaration of Conformity stating how many square inches of both fluorescent fabric and tape are present on the garment, who makes these materials and the latest test report number ensuring those materials meet the requirements of ANSI/ISEA 107-2020.

GLOWEAR® 8246Z

SMALL/MEDIUM CHICO/MEDIANA

TWO-TONE VEST // LIME

CHALECO DE DOS TONOS // LIMA

Machine Wash Cold, No Bleach, Tumble Dry Low, Do Not Iron, Do Not Dry Clean.

100% Polyester

This Garment Does Not Meet the FR Requirements of ANSI/ISEA 107-2020 Section 10.5

Lavable a maqulna con agua fria.

No usar blanqueador.

Usar secadora en modo bajo.

No planchar. No limpair en seco.

100% Polyester

Esta prenda no cumple con los requisitos de resistencia al fuego de la norma ANSI/ISEA 107-2020, seccion 10.5

MANUFACTURED BY FABRICADO POR

021 BANDANA BLVD EAST // SUITE 220

SAINT PAUL, MN 55108

800 225 8238 // ERGODYNE.COM

MADE IN INDONESIA

HECHO EN INDONESIA

Resources

SHINE SCHOOL IS NOW IN SESSION

The deeper you dive, the brighter you become. Take hi-vis even higher with comprehensive guides to ANSI/ISEA 107-2020, biomotion and more.

Guides & Documents

Videos

Blog Articles

Understanding Hi-Vis Standards: ANSI/ISEA 107

Understanding Hi-Vis Standards and the Importance of Replacing Used High Visibility Apparel

What is Biomotion and How Does it Relate to Hi-Vis Clothing?

Frequently Asked Questions

ANSI/ISEA 107 outlines specific requirements for labeling and design including minimum amounts of certified fluorescent background material and retroreflective tape. When in doubt, check the label. Every ANSI/ISEA 107-2020 garment must be labeled as such by the manufacturer, who must also have a declaration of conformity on file.

More information about ANSI/ISEA 107-2020 standards can be found here.

ANSI/ISEA 107-2020 is the industry regulation that sets design, labeling and performance criteria for all types and classes of high-visibility wear, particularly the amount of required fluorescent background material and retroreflective to keep workers safe and seen.

OSHA standards require such employees to wear high visibility garments in two specific circumstances: when they work as flaggers (1) and when they are exposed to public vehicular traffic in the vicinity of excavations (2). However, other construction workers in highway/road construction work zones are also exposed to the danger of being struck by the vehicles operating near them. for such workers, section 5(a)(1) of the OSH Act, 29 U.S.C. §654(a)(1), also known as the General Duty Clause, requires similar protection.

The Federal Highway Administration's (FHWA) recent issuance of a final rule (Worker Visibility, 23 CFR Part 634)4 demonstrates the need for all workers who are exposed either to public traffic or to construction vehicles and equipment to wear high-visibility apparel5. Section 634.3 of the Worker Visibility Rule states: All workers within the right-of-way of a Federal-aid highway who are exposed either to traffic (vehicles using the highway for purposes of travel) or to construction equipment within the work area shall wear high-visibility safety apparel. Source: OSHA.

Approved fluorescent colors are lime, orange and red. These colors enhance daytime visibility by adding contract against background environment.

Solid, segmented and combined performance.

-

Struck-by flying objects

-

Struck-by falling objects

-

Struck-by swinging objects

-

Struck-by rolling objects

| Class | When to Wear | Garment Requirements |

| Class 1 | Intended for locations where the worker is separated from traffic, which is traveling no faster than 25 mph, and for workers whose tasks don’t divert their attention from approaching traffic. |

|

| Class 2 | Intended for workers whose tasks divert their attention from approaching traffic and for those who must work near vehicles exceeding 25 mph. Provides enhanced visibility during inclement weather. |

|

| Class 3 | Provides maximum visibility for workers who have tasks that place them in imminent danger from approaching traffic. Provides maximum visibility when the wearer must be conspicuous at a minimum distance of 1,280 feet. |

|

| Class E | Intended for increasing the visibility of the lower body. Garments that do not classify when worn alone, but achieve Class 3 when worn with other Class 2 or Class 3 garment |

|

The standard breaks out the garments into three types of worksite environments.

Type O = Off-Road // Type R = Roadway // Type P = Public Safety

More information about the different Types of hi-vis apparel can be found here.

For off-road, indoors or controlled environments, parking lots, festivals, extracting/refining oil & gas, warehouse and factories.

For environments with moving traffic or equipment traffic. Minimum level of protection for workers exposed to roadway rights-or-way and temporary traffic control (TIC) zones.

Police, fire and EMS only.

| Class | Type of Worker |

| Class 1 | Parking service attendants, warehouse workers in traffic, shopping cart retrievers and those doing sidewalk maintenance. |

| Class 2 | School crossing guards, parking and toll gate personnel, airport ground crews and law enforcement personnel directing traffic. |

| Class 3 | Roadway construction flaggers, workers in high speed traffic areas, workers in cluttered backgrounds that could interfere with visibility. |

Jobsite wear and tear is inevitable. Recognizing your gear’s service life is critical to staying safe. Retire your hi-vis if the fabric or reflective is torn/cracked, heavily soiled, faded or dull, burned or otherwise damaged or no longer comfortable.

Where there’s high activity, there’s struck-by risk—but especially in industries involving heavy machinery (75% of fatalities involve equipment such as trucks or cranes). #1 Construction, #2 Manufacturing, #3 Trade, Transportation & Utilities.

Make sure you and your crew are wearing high-visibility apparel, that it is certified to the ANSI/ANSI 107-2020 standard, and that it is clean and in good working condition.

Enforce the use of hard hats and safety helmets, provide safety eyewear, tether tools to work belts and ensure workers are highly visible.

Stay alert in work zones, inspect tools and equipment, lower blades and lock moving parts of machine when not in use, make internal and external traffic control plans, plan for a safe crane and lift zone and limit access to work areas.