What is Biomotion and How Does it Relate to Hi-Vis Clothing?

Why proper reflective material is crucial for hi-vis clothing

In 1895, the first domino fell in what would ultimately become modern-day Daylight Savings Time when George Hudson proposed a two-hour daylight-saving shift. A shift worker by day and entomologist by night, Hudson sought additional after-hours daylight for collecting insects. Over a decade later, in 1908, Port Arthur, Ontario became the first city to enact DST. And, well, you know the rest (unless, of course, you live in Arizona—by the way, what’s up with that?).

For many laborers, Daylight Savings Time is but a formality—burning the midnight oil on graveyard shifts or clocking in before the birds. And, regardless of which side of the darkness you’re on, the key to staying safe is staying seen.

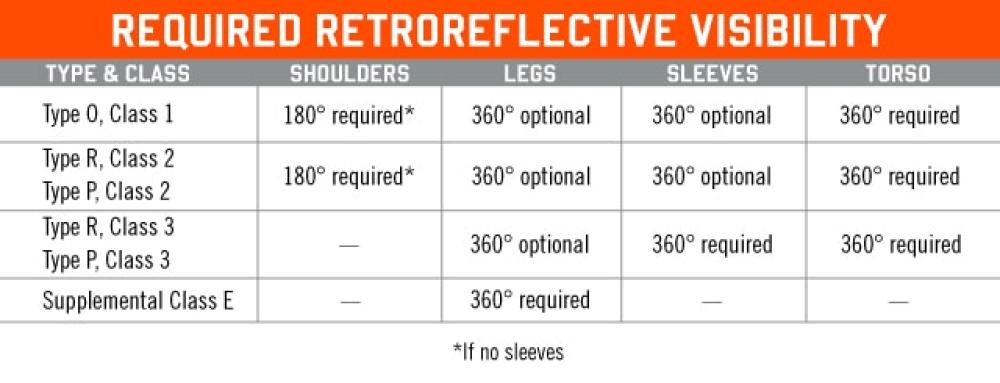

If you missed our 4-1-1 on Hi-Vis Standards, ANSI/ISEA 107 is the industry standard that sets design requirements for high-visibility apparel. These standards not only apply to yellow and orange fluorescence, but also designate the width and amount of ANSI-compliant retroreflective material required to enhance visibility in low-light environments (ie., the night shift).

BIOMOTION + ANSI 107 HI-VIS STANDARDS

A major consideration in development of the ANSI 107 standard is biomotion which, very simply put, is the movement that signals awareness to the brain that it is looking at a living, breathing thing. It’s what tells you, “Hey, buddy, that’s not a traffic cone—it’s a worker,” as you’re cruising down the street in your ‘64.

Biomotion is why ANSI 107 always requires 360-degree visibility on the torso and, depending on the class, requires 180-degree and 360-degree visibility on shoulders, sleeves and pant legs—which, for those guessing at home, is where retroreflectivity comes in.

Retroreflective strips reflect light back at its original source (headlights, for example). Strategically placing reflective tape around the most mobile parts of the body (arms and legs) reflects not only the shape, but the movement of workers that triggers recognition that a worker is not a static object.

X-Back Safety Vests

While the standards remain the same, there are stylistic choices that workers can make to increase their safety even more while working in dimly lit environments. An X-back safety vest features retroactive material in the shape of an “X” on the back of the vest, as opposed to a standard “U” shape that mimics the front of the vest. This “X” allows a worker to communicate their orientation, in turn allowing others to know what way they are facing.

So, why does it matter if other people know you are facing the other way? Well, someone may assume that you will move if you see a threat approaching. However, when the “X” is visible and it is clear that a worker’s back is to the forklift, the car or any other threat — meaning that fellow workers or civilians can make more informed decisions and protect those around them — because we don’t know how to protect ourselves from the things we can’t see.

X-back safety vests are frequently used by roadway and traffic workers, construction workers and warehouse & distribution workers. The “X” ensures they remain visible in low-light environments and prevent accidents in high-traffic areas while the worker’s back is turned, both indoors and outdoors. Railway workers also wear an X-back safety vest as they meet Transport Canada and FRA Regulations for railway safety. Finally, emergency responders and maintenance & utility crews rely on X-back safety vests to keep them visible during roadside assistance or emergency situations.

TAPE TYPES: SOLID VS. SEGMENTED

When it comes to high-visibility clothing, the type of reflective tape used can make a big difference in both performance and comfort. Solid tape is the “traditional” option; it's a continuous, non-breathable strip of reflective material that offers reliable durability and visibility. It’s commonly used in heavy-duty garments because it stands up well to wear and tear. However, solid tape can feel stiff, especially on lighter fabrics, and it can restrict movement or trap heat, which isn't ideal for physically demanding work in warm environments.

Segmented tape, on the other hand, is made up of small reflective pieces arranged in a pattern (often stripes or broken lines). This design allows the tape to move and stretch with the fabric, making garments more breathable, flexible and comfortable, especially for active workers. It’s a popular choice in modern performance workwear and women's PPE because it provides the required visibility while allowing for better fit and freedom of movement. Ultimately, the choice depends on the work environment and how much flexibility, durability and comfort your gear needs to deliver.

Visible From Every Angle

The ability to encircle the body for 360- and 180-degree visibility is what sets reflective tape apart from lighted vests and clips. Though the flashing of these devices signifies drivers to proceed with caution, they are not able to accurately reflect the body’s movement—leaving workers to look no different than a flashing stop sign. And while we don’t imagine anyone is actively looking to add a dent to their fender in any case, the stakes are understandably a little higher when another human life is involved.

Moral of the story? When it comes to keeping crews safe from dusk ‘til dawn, there’s no need to complicate things. When combined with the right class and type of hi-vis clothing, reflective tape does the heavy lifting to keep workers seen—without lighting them up like human Christmas trees.

FAQ

The X-shaped reflective striping on the back of a vest helps distinguish the worker’s back from the front. This makes it easier for others, such as equipment operators or drivers, to recognize when a worker is facing away from them.

In the United States, X-back striping is not required by OSHA or ANSI/ISEA standards. However, in Canada, the CSA Z96 standard mandates X-back designs for most Class 2 and Class 3 safety vests.

Both designs provide retroreflectivity, but the X pattern provides clearer directional recognition. Vertical stripes may show visibility, while the X-back immediately signals orientation (front vs. back), which can be critical around moving vehicles.

X-back vests are most commonly worn by workers in Canada, as well as in industries where orientation awareness is critical, such as road construction, railway, and traffic control.

Railways often require X-back striping because it helps operators and crew quickly recognize whether a worker is facing toward or away from an oncoming train or equipment, reducing the risk of accidents.