What is the ANSI/ISEA 138-2019 Standard for Impact Testing & Dorsal Protection?

Dorsal (dor•sa)l: being or located near, on, or toward the upper surface of an animal as opposed to the lower or ventral surface. Merriam-Webster

Consider the back of your hand. The dorsal surface of the hand. The more vulnerable side. It often doesn’t get the respect or attention it deserves. The dorsal surface of the hand has thin padding, exposed bones, blood vessels and tendons. The palm side, in contrast, like a baseball mitt, has thicker padding, and fewer exposed bones, and possibly the extra protection of calluses built up over years of work.

Dorsal protection most often uses thermoplastic rubber (TPR ) securely stitched into impact gloves, vibration gloves and cut-resistant gloves. With its elasticity and rubber-like material, TPR effectively disperses impact energy away from the 14 bones (phalanges) found in the fingers of each hand; the knuckles; the five metacarpal bones that compose the middle part of the hand; and the eight carpal bones that create the wrist. The thickness of the TPR material increases the distance between the impact and the hand. TPR elasticity smashes, or “gives” a bit to increase how long the impact lasts.

Dorsal protection also disperses impact energy away from the numerous muscles, ligaments, tendons, sheaths, arteries, veins and nerves within the hand.

Stop and think about it. Your hands are a complex piece of anatomy.

Where We Started: ANSI/ISEA 105-2016

Glove manufacturers, through the International Safety Equipment Association (ISEA), first set a voluntary standard in 1999 to protect or reduce deleterious effects on the wearer of a glove—ANSI/ISEA 105-2016

The standard has been through numerous revisions. The most recent edition, ANSI/ISEA 105-2016, protects hands against cuts, tears, punctures, hypodermic needles, abrasion, chemical permeation, chemical degradation, heat degradation, conductive heat, flame and vibration.

But what about those crushing blows to the dorsal surface of the hand? Lacerations and cuts are the most common injuries to the hand, but blunt trauma, due to the force and weight usually involved, often are severe injuries involving fractures and broken bones.

For decades workers have worn impact gloves, impact-resistant gloves, high-impact gloves, anti-impact gloves—some variation of impact protection gloves. But who’s to say what the true impact performance was? Choosing an anti-impact glove was a bit of a guessing game.

Where We Are Now: ANSI/ISEA 138-2019

That question was answered in 2019 with the introduction of ANSI/ISEA 138-2019, The American National Standard for Performance and Classification for Impact-Resistant Gloves. The dorsal surface of the hand now has the respect and attention it warrants. ANSI/ISEA 138-2019 establishes testing, classification and labeling requirements for work gloves providing dorsal protection.

These impact gloves are commonly used in the automotive industry, heavy equipment and construction operations, cargo handling, oil and gas and towing/transportation industries. Compliant gloves are evaluated for their capability to dissipate impact energy on the knuckles and fingers and are classified into three levels of performance. Now employers can reliably compare different impact gloves on an equal basis when making selections.

Here is how ANSI/ISEA 138-2019 conducts impact tests:

- Testing must be performed by an independent and accredited ISO/IEC 17025:2017 laboratory.

- All gloves tested are kept in the same environment, including the temperature of the glove. The gloves are cut in half and the back of hand side (good ole dorsal) is placed on a slightly curved anvil.

- A striking mass weighing about 5.5 pounds is dropped like a hammer to simulate an impact or blow. A force transducer beneath the anvil measures how much impact force on average would travel through a glove to a worker’s hand. On both right- and left-hand gloves, each knuckle is tested four times and fingers/thumbs are tested five times. The average of the knuckle tests is compared to the average of the ten-finger tests and the lower performing average of the two is the final impact test score.

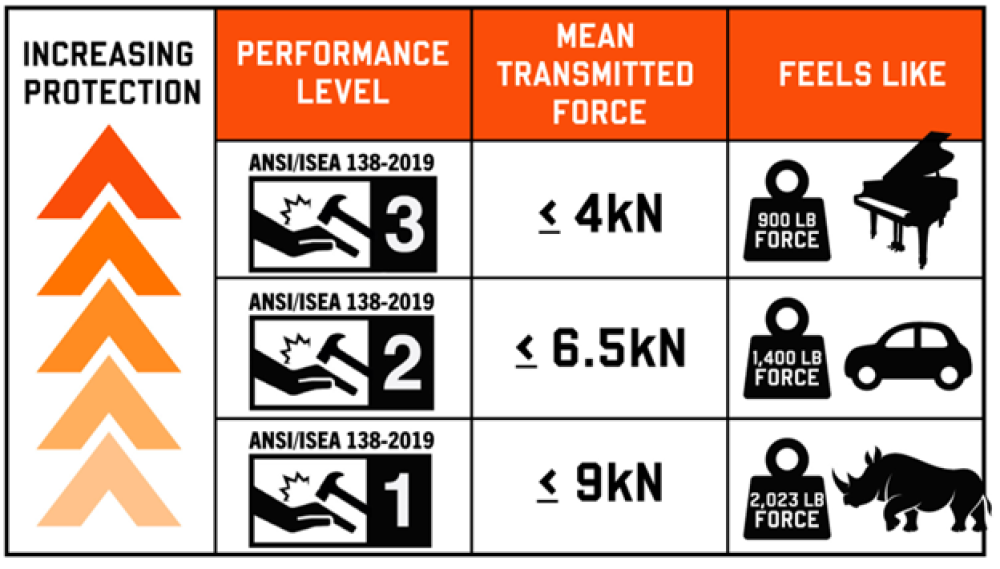

ANSI/ISEA 138-2019 Levels of Performance

Based on results, gloves are assigned a Level 1, Level 2 or Level 3 rating. All performance levels are displayed directly on the gloves to provide a simple visual of the level of performance.

- Level 1 gloves allow an average of 9 or less kilonewtons (kN) of force through the glove.

- Level 2 gloves allow an average of 6.5 or less kN of force through the glove.

- Level 3 gloves allow an average of 4 or less kN of force through the glove.

The less force transmitted through the glove the stronger the protection. Level 3 gives you the most protection. Level 1 gives the least protection.

4 kilonewtons of force equals approximately a 900-pound-force. That’s about the weight of a Steinway Model D Concert Grand Piano.

6.6 kilonewtons of force equals approximately a 1,400-pound-force. That’s almost the weight of a blue whale’s heart, which is the size of a small car. Speaking of small cars, a dirt-chewing World of Outlaws stripped-down, tube-frame open-wheel dirt racer weighs about 1,400 pounds.

9 kilonewtons of force equals approximately a 2,023-pound-force – or one ton. Imagine a Pacific Walrus (2,000 to 4,000 pounds), a Black Rhinoceros (2,000 to 2,500 pounds), an American Bison (up to 2,200 pounds), a Leatherneck Turtle (2,000 pounds) or a hot tub (2,000 pounds) dropped on one of your hands.

There's No Excuse When It Comes to Proper Hand Protection

Makes you wonder why anyone would leave their gloves in the locker. Maybe they don’t know the U.S. Bureau of Labor Statistics (BLS) estimates roughly one in five work-related injuries are to the hands. Or more than one million workers are sent to the emergency room annually with hand injuries, according to the BLS. Or that wearing gloves reduces the relative risk of hand injury by 60 percent. Or maybe they don’t know the definition of dorsal protection.

The old excuses that “I can do it better with my own hands” or complaints about gloves being too bulky, too hot or interfering with dexterity don’t hold up in 2023.

Ergodyne ProFlex® dorsal impact-reducing gloves use durable TPR armor across knuckles and fingers for dorsal protection rated ANSI/ISEA 138-2019 Level 1 for forceful impacts, pinch injury protection and blow deflection. Ergodyne gloves also feature strong no-slip grip; no sweat palms; flex zones that move with you for enhanced dexterity and reduced hand fatigue; 360-degree breathability with a cool-to-the touch feel. Some models feature touchscreen-capable fingertips that make it easy for workers to swipe, tap and type on smartphones and tablets without having to remove their work gloves.

Brutal crushing, blunt trauma injuries to the hands can cause fractures, dislocations, contusions, tendon and ligament damage, and in the most severe cases, amputations. Lost workdays often result. Imagine a rhino or a leatherneck turtle dropped on your hand. Reduce the risk of losing the use of one of the most complex and beautiful pieces of natural engineering in the human body, and the most used body part – the hand. Today you can choose from a marketplace chock full of impact gloves, vibration gloves, impact-resistant gloves, high-impact gloves, anti-impact gloves and impact protection gloves. Make sure you choose the right glove for the job.