Finding the Best Cut-Resistant Work Gloves to Reduce Hand Injuries for one of the World’s Largest Brewers

When the gloves being used at one of the world’s largest breweries kept falling prey to the facility’s many cut hazards, Ergodyne came through with an all-in-one solution to keep workers safe.

At a facility for one of the world’s largest brewing companies, cut hazards abound. But the gloves workers were using just weren’t up to the challenge. Luckily, ProFlex’s new line of coated cut-resistant work gloves had just the solution—and then some.

THE HAND INJURY HAZARD[S]

Between brewing, bottling/canning and equipment maintenance, a day at the brewery presents plenty of opportunities for hand injuries—particularly due to high amounts of broken glass.

Because sweeping up messes puts the product at risk for dust contamination, every piece of glass must be picked up by hand. And beyond the frequent cleanup required to keep the facility contamination-free, there’s also maintenance and operation of the glass crusher (a machine that’s name speaks for itself…).

But glass is only half the battle. For quality control, razor sharp cans also have to be wiped before tops are put on—presenting workers with yet another high cut risk.

THE PROBLEM: WEAK CUT-RESISTANT GLOVES = WORKER INJURIES

All of that demanding use was putting the brewery’s A4 cut-resistant gloves through the ringer, requiring frequent replacement due to the speed at which the palms were breaking down.

And when those breakdowns started resulting in recorded hand lacerations, the safety manager knew a better solution had to be found—and fast.

TESTING: FINDING THE RIGHT HEAVY-DUTY GLOVES FOR THE JOB

Having recently extended their Coated Glove Series, Ergodyne was more than equipped for the challenge—presenting the brewery with not one but two brand new level A7 cut-resistant work gloves.

Touting one of the highest levels of cut resistance available, the ProFlex 7071 and 7072 would provide a significant boost in protection and durability over the A4 they had been using. And because Ergodyne built both gloves using comfortable and lightweight 18-gauge tungsten knit, that bolstered protection does not come with the itchy hot discomfort often found in incredibly high cut-resistant gloves.

When the brewery put them to the test, the hypotheses proved true. Workers loved both of the gloves’ insane cut protection and abrasion resistance, as well as the “second skin” feel of the 18-gauge tungsten knit.

But which ProFlex A7 glove would ultimately reign supreme on the brewery battlefield?

AND THE WINNER IS… PROFLEX 7072 A7 CUT-RESISTANT WORK GLOVES

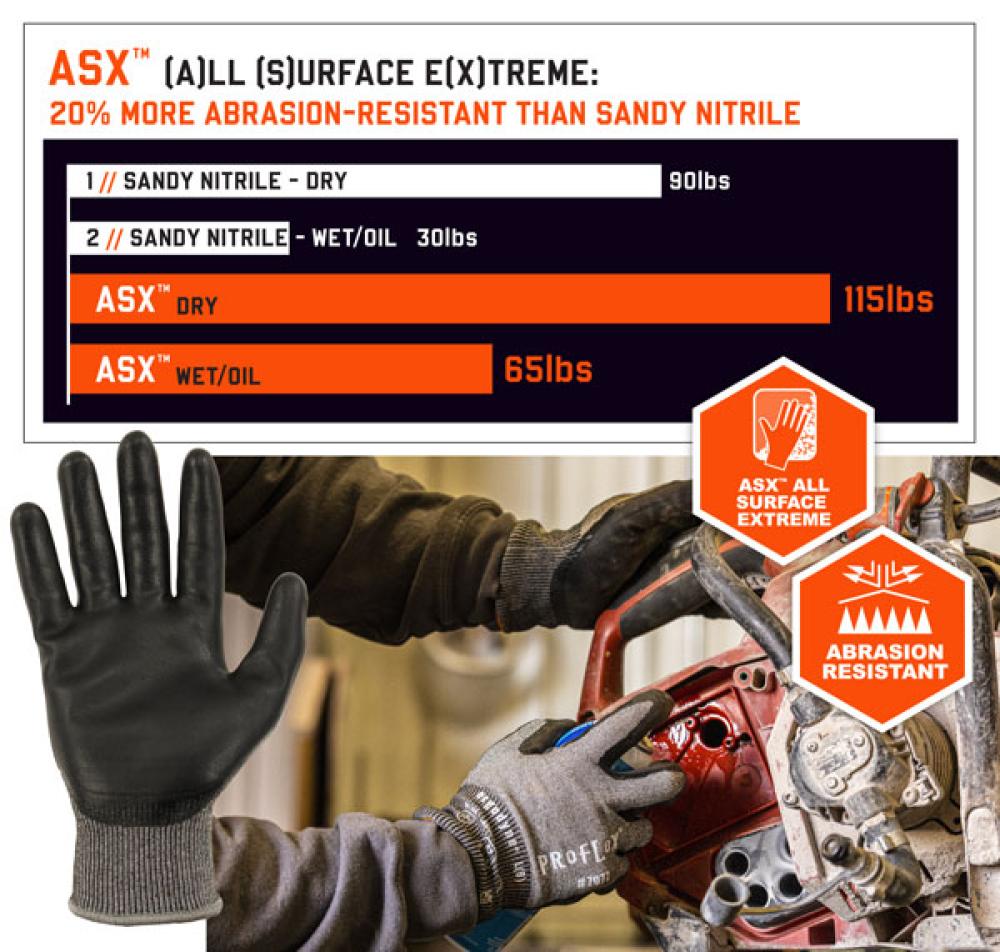

Because of the frequent handling of wet bottles and cans, the deciding factor was the 7072’s ASX™ (All Surface Extreme) grip. With a 20% better grip performance than sandy nitrile and the highest possible abrasion resistance (level 6), the durable dual-layer nitrile coating makes the 7072 one of the industry’s best gripping gloves on any surface—wet, oily or dry.

BONUS! CUT-RESISTANT SLEEVES & DORSAL PROTECTION GLOVES

Along with the successful trial of the 7072, the brewery also traded up for the ProFlex 7941 ANSI/ISEA 105-2016 A4 Cut-Resistant Sleeves and 922CR Nitrile-Coated Dorsal Impact Protection Gloves. The A4 cut sleeves delivered on the extended protection workers needed with the stay-in-place fit and breathable no-itch feel their current aramid sleeves were lacking. And for those regularly pinching and bruising their fingers while rolling or stacking heavy kegs, the 922CR gloves provided much-needed back-of-hand protection.

INNOVATION THE COMPETITION CAN’T TOUCH

When it comes to keeping workers safe and productive, we’d pit the ProFlex 7072 (and every other glove in the line, for that matter) against anything else on the market. From industry-leading grips to breakthrough yarn technologies and a full range of ansi-level cut resistance, ProFlex is out to prove the best gloves are the ones that get worn.