How to Implement a Dropped Object Prevention Plan - Part 2

The following is the second post in a four-part series on implementing a dropped objects prevention program. In part two, we’ll look at the next two steps, observing and assessing your pilot area, and properly training personnel within it. If you missed Part 1, you can read that here: How to Implement a Dropped Objects Prevention Plan - Part 1.

Like climbing ladders or stairs, there are steps to take to implement a dropped objects prevention plan on your jobsite. Regardless of industry, your roadmap to a successful dropped objects program should be:

- Call to Action

- Identify Risk & Define Scope

- Observation/Site Assessment

- Training

- Controlled Implementation

- Policy Creation

- Launch

- Review & Expand

OBSERVATION/SITE ASSESSMENT

To assess a worksite, spend time monitoring at-heights work. This observation period will allow you to identify and analyze potential and actual safety hazards, which may vary from jobsite to jobsite. In part one of our series, we defined the scope by beginning with a pilot area to start your efforts. Concentrate your observations in this pilot area. This will give you more focus allowing you to perfect your observation skills on a smaller scale to start.

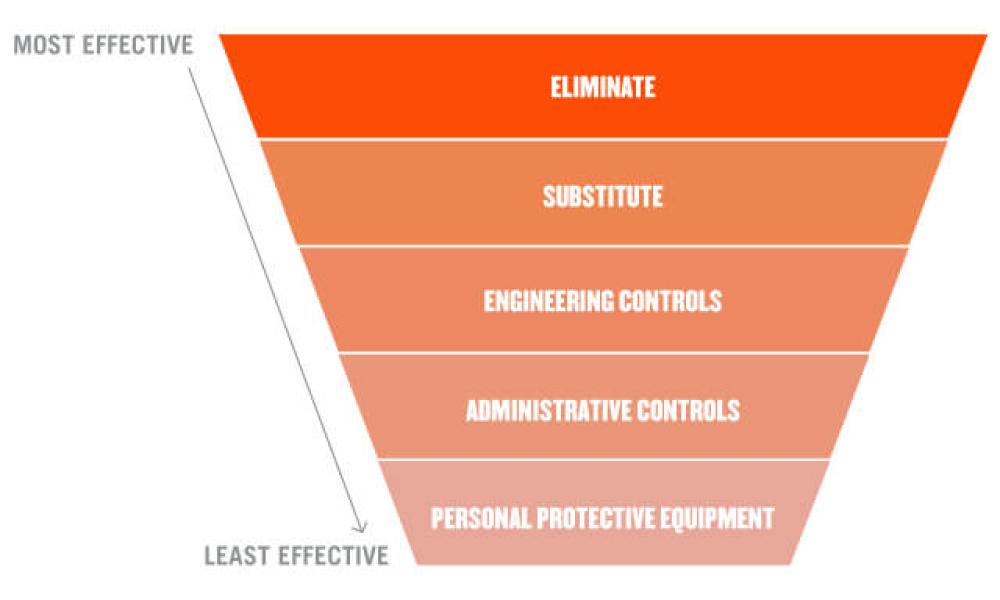

Once that’s done, you can begin to work through the hierarchy of controls (HOC) to seek safety solutions for the pilot area. Consider tethering and topping solutions, anchor points, clearance, and other challenges/competing hazards that may complicate your efforts. Be sure to document your discoveries and ideas, and file those away for future reference.

Think about levels other than the one on which you’re standing. Dropped objects causes can originate on the ground before acceding to height or happen while at height. There are several factors that can lead to them, including:

- Elements

- Worker-generated situations

- Poor housekeeping

- Improper equipment transport

- Site risks

Unsafe Conditions

These are issues with physical items that are tangible and visible. Go around your worksite and think about clearance considerations; anchor points (but be sure to differentiate objects at heights and personnel fall anchor points); and tools and equipment like chemicals, rotating tools, etc. that are being used on the jobsite.

Establish a system to differentiate anchor points by color coding or tagging them another way. Are tool tethering anchor points available? Are they being improvised or misused? If they are not available, consider retrofit solutions that can be added. If there are stationary passive engineering controls like guardrails, nets, toeboards or others, inspect them and insure there are inspection practices in place for them.

Unsafe Acts

Unlike unsafe conditions, unsafe acts are factors related to administrative controls, which aren’t physical “things” that can be fixed. These can include:

- Work sequencing

- The plan

- Complacency

- At-heights access for workers

- Equipment transport

Fill out an Objects at Heights Hazard Evaluation Form and a Pre-Task Plan. This will help you organize your thoughts, and get decisions and events on record.

Dropped Object Prevention Training

Set the stage by holding initial O@H training. There, you can identify workers whom you may want to be involved in a pilot study and other safety managers. Next, choose your workplace safety champions. These should be responsible colleagues whom you trust to follow the rules and set a positive example for their co-workers.

Two champions should be chosen:

Tools and installations leader:

- Oversees tool crib

- Manages tool inventory documentation

- Reviews new tools entering job

Process & use leader:

- Manages personnel doing job(s)

- Identifies and marks anchor points

- Considers other factors/competing hazards (i.e., ergonomics)

Other important safety roles/responsibilities that you can set up on your site may include:

It may be tempting to hurriedly implement a dropped objects prevention program after an incident occurs, but that can result in missteps and mistakes. Being methodical, analytical and thorough in detailing a plan is the only way to create real and meaningful change in your workplace safety culture.

Part Three of our series will focus on the controlled implementation and policy creation of your program. Read Part 3 and Part 4 now.