Hearing protection: OSHA requirements and choosing the right solution for you

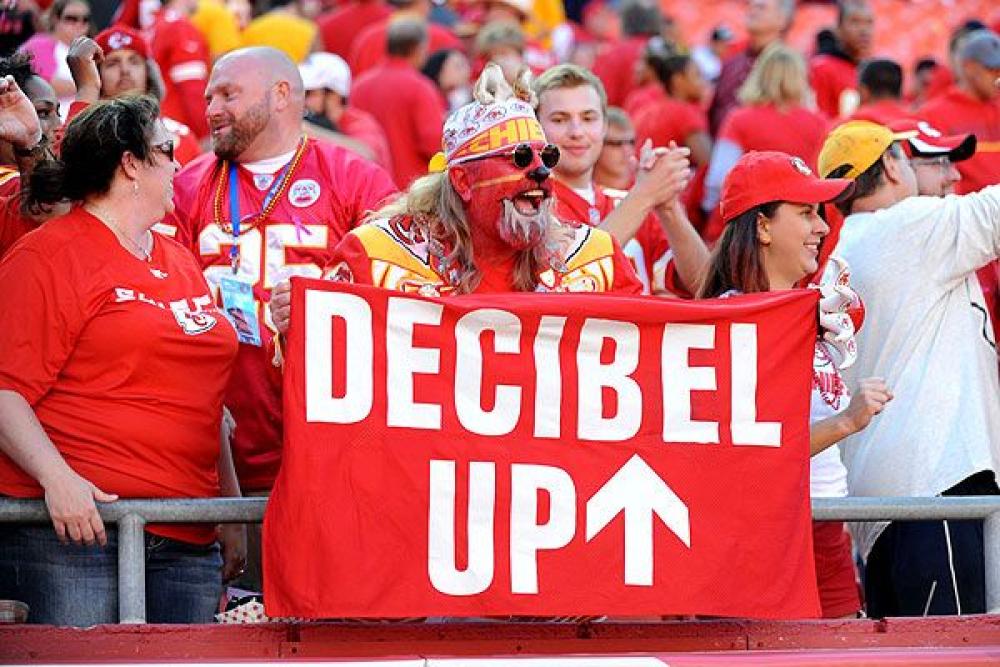

Of all the hazards faced by workers, noise might be the most insidious. Sure, if you’re with 77,000 Kansas City Chiefs fans in Arrowhead Stadium, with crowd noise cranked up to 142.2 decibels, you’re screaming but you can’t be heard. If you’re standing next to a Top Fuel car that breathes fire at more than 150 decibels, you worry about your eardrum shattering.

But if you’re at a nightclub where noise can reach 100dB, are you thinking about dB levels? Just another night out. If you’re pushing a lawnmower with an average noise of 94dB, are you bothered? You’ve mowed the lawn hundreds of times.

That’s the danger of noise. We get acclimated to it, especially at work. And noise does its damage over time, day after day, year after year, killing inner ear hair cells usually without us realizing we’re slowly losing our hearing. Hearing loss is often discovered and recorded in the annual audiogram required by OSHA for each employee exposed at or above an eight-hour time-weighted average of 85dB. The loss is not always painful. Sure, if you’re standing next to a jackhammer or a gun shot blast without wearing hearing protection, that sonic burst can stun you, leaving your ears temporarily ringing.

OSHA Hearing Protection & Conversation

But 22 million workers in the U.S. are regularly exposed to potentially damaging noise, according to the Centers for Disease Control. OSHA mandates that any workplace averaging 85dB for an eight-hour average exposure must put in place an effective hearing conservation program. (On construction sites it’s a 90dB threshold.) If you need to raise your voice to speak to someone three feet away, noise levels might be above 85dB.

Industries most cited by OSHA for hearing protection violations:

- Manufacturing

- Wholesale Trade

- Waste Management and Remediation Services

- Construction

- Arts, Entertainment, and Recreation

- Agriculture, Forestry, Fishing and Hunting

- Accommodation and Food Services

- Retail Trade

Protecting and preserving your hearing can make a huge difference in your quality of life. Permanent hearing loss cannot be corrected through surgery or medicine. Hearing aids can help, but they won’t restore your hearing to normal. Your conversations, taken for granted for so many years, may never be the same. Music, movies, TV shows, podcasts, you’ll have to crank ‘em up and hope you don’t annoy whoever is with you.

OSHA requires employers to follow a hierarchy of controls to keep the noise down in workplaces. The first strategy, installing engineering controls such as modifying or replacing equipment, often is not economically or technically feasible. The second option, limiting the time a person spends at a noise source, is often impracticable. Personal protective equipment in the form of hearing protection devices is the most common line of defense.

Types of hearing protection

There is an assortment of industrial hearing protection devices (HPDs) to choose from:

- Expandable foam plugs: Plugs are made of a formable material designed to expand and conform to the shape of each person’s ear canal. A plug is also available that is essentially a foam tip on a stem. You insert this plug much like a pre-molded plug without rolling the foam.

- Canal caps: Canal caps often resemble earplugs on a flexible plastic or metal band. The earplug tips of a canal cap may be a formable or pre-molded material. Some have headbands that can be worn over the head, behind the neck or under the chin.

- Earmuffs: Earmuffs block out noise by completely covering the outer ear. Muffs can be “low profile” with small ear cups or large to hold extra materials for use in extreme noise. Some muffs also include electronic components to help users communicate or to block impulsive noises.

- Impulse noise protection earmuffs (also called electronic earmuffs): Earmuffs electronically filter out constant, loud noise and short bursts of high-volume noise. These electronic hearing protection earmuffs reduce, or attenuate, loud noises while still allowing you to hear ambient sound. Electronic ear protection is often worn to protect against impulse (or impact) noises such as gunfire or metal stamping, pressing, and forging sounds.

Other noise canceling earmuffs passively block noise by relying on the insulating materials of the ear cups to dampen sound. They're typically worn in areas where workers don't need to speak with one another and the goal is to block all or most surrounding noise. As the NRR of these earmuffs increases, they tend to get bulkier due to the larger ear cups and increased insulation materials.

Selecting Hearing Protection PPE

Keep in mind no single industrial hearing protector fits all people. Devices address a variety of workplaces environments and conditions, including different decibels levels, specific industries, as well as different communication requirements.

The first step in finding the right hearing protection is to determine what the noise level is in your workplace. OSHA requires measuring noise exposure with a sound level meter or noise dosimeter or both. Measurements should be taken at different times to help determine the different noise levels experienced throughout a workday. Employee movement and sound instrument calibration and maintenance should also be considered in a comprehensive measurement program.

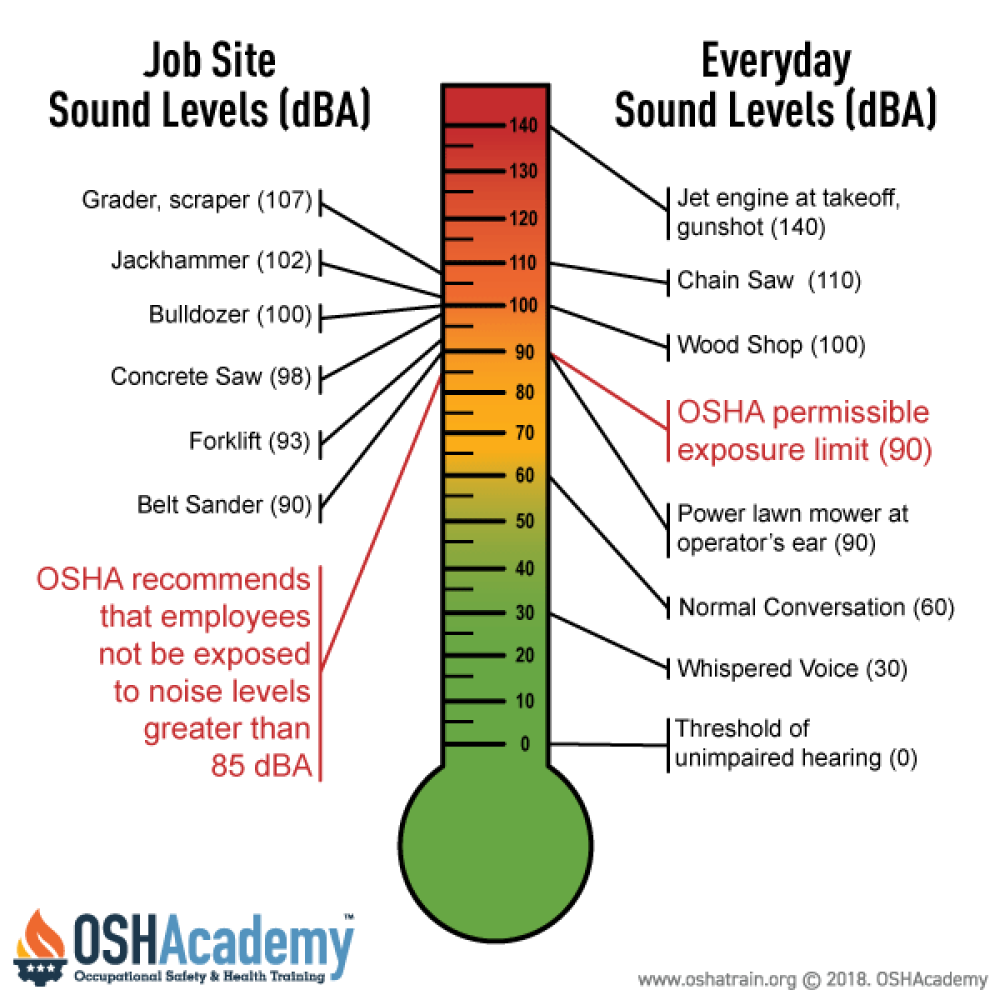

OSHA and ANSI’s sound level estimates chart uses a thermometer-type image to rank on the left side job site sound levels as low as a framing saw (82dB), a backhoe (85dB), and up to a bulldozer (100dB), jackhammer (102dB), grader and scraper (107dB) and a chain saw (110dB). On the right side of the thermometer are everyday sound levels, ranging from a whispered voice (30dB), normal conversation (60dB) to a jet engine at takeoff (140dB) and a gunshot (140dB).

Noise reduction ratings

Once the noise level of a work area is determined, you can look at the noise reduction ratings (NRR) of hearing protectors to decide how much attenuation is needed to bring the worker’s exposure below the 85dB threshold. The NRR is a common method for expressing values of noise reduction or attenuation provided by different types of hearing protectors; values range from 0 to approximately 30. The higher the NRR number associated with a hearing protector, the greater the potential for noise reduction.

Noise reduction ratings are important because they indicate the functionality of a device, and the ability of that device to protect hearing in noisy environments.

To approximate an NRR, break out a calculator. Industrial hearing protectors do not reduce the decibel levels in the workplace by the precise decibel reduction number on the NRR label because the hearing protector was tested in a lab, not in the field. Say a person working in a loud occupational environment is exposed to noise at 94dB(A). If the individual is wearing hearing protection equipment with an NRR of about 26dB(A), you would think the noise exposure amount would be lowered to 68dB(A). Wrong. Instead, it would be lowered to 84.5dB(A), below the OSHA threshold of 85dB. How is this calculated? OSHA has methods for estimating the adequacy of hearing protection attenuation. One method’s calculation includes:

- Subtract seven from the NRR number, which is given in decibels (26dB – 7 = 19)

- Divide the result by two (19 / 2 = 9.5)

- Subtract the result from the original workplace noise exposure level in decibels (94dB – 9.5 = 84.5)

What if you are wearing two sets of ear protectors? How is the NRR calculated? This method’s calculation includes:

- Determine NRR rating of each individual ear protector (Earplugs 33dB NRR and Earmuffs 26dB NRR)

- Take the higher NRR rating (Earmuffs 26dB NRR)

- Add 5dB NRR to that number (Earmuffs 26dB NRR + 5dB NRR)

- New NRR rating for earplugs + earmuffs = 38dB NRR

Training on the proper use of hearing protectors should include individual fit testing to measure how well the devices fit each person.

What’s the best ear protection for you?

So what’s best for you? Disposables or reusables? Earplugs or earmuffs? The first thing to do is find adequate protection. Second, make sure the hearing protector is compatible with other PPE or communication devices. And then there is the age-old challenge of compliance – making sure the hearing protection is comfortable and convenient enough to be accepted and worn, not found dangling around the neck, stuffed in a pocket or flipped up on hard hats. Despite decades of knowledge about the dangers of high noise and hearing loss, NIOSH declares occupational hearing loss the most common U.S. work-related illness in manufacturing.

Factors influencing hearing protection compliance:

- Ensure proper fit. Hearing protection that doesn’t fit is uncomfortable, irritating, and often not used.

- Make sure the hearing protection is right for the job. Know your work area noise exposure levels.

- Don’t over-protect workers by giving them hearing protection that reduces noise levels more than is needed. Some workers will complain they can’t hear alarms or talk to co-workers.

- Are you required to use other over-the-head PPE? Hearing protectors need to be integrated with this equipment.

- Are you wearing gloves or do your hands get dirty? This can make using roll ‘em up ear plugs hard to handle.

- Do you work in tight or confined spaces? Use low-profile hearing protection so workers won’t remove it if it’s too bulky or awkward fitting.

- Is your work environment particularly hot or cold? Make sure hearing protection materials match the environment they’ll be used in.

Provide your employees with the opportunity to select their hearing protection from a variety of suitable devices. This is a mandate in OSHA noise standard. And it’s one OSHA mandate easily met.

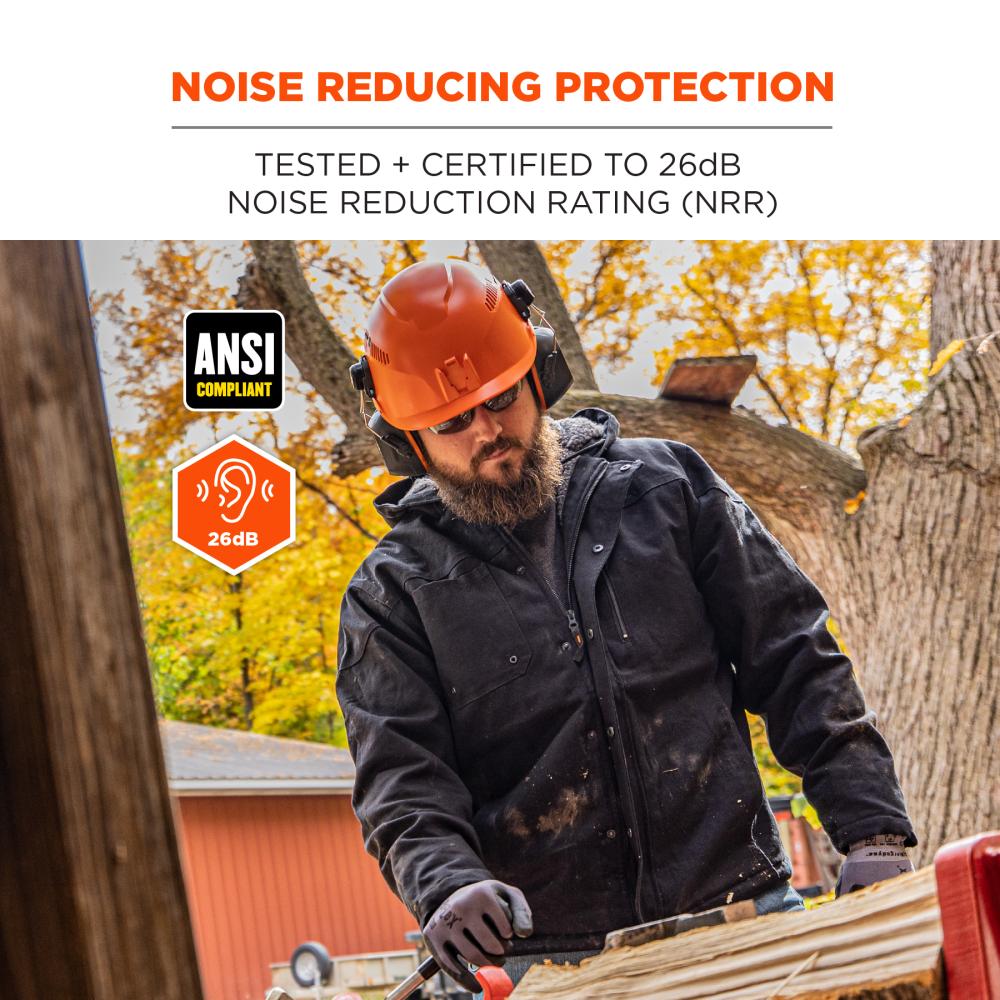

The marketplace for industrial hearing protection features all the types of protection needed for any situation. One example, Skullerz 8880 NRR 26dB Hard Hat Mounted Earmuffs, designed for all-day comfort and for hard hat and safety helmet integration.

CHECK OUT SKULLERZ HARD HAT MOUNTED EARMUFFS >>

FAQ

OSHA mandates that any workplace averaging 85dB for an eight-hour average exposure must put in place an effective hearing conservation program. (On construction sites it’s a 90dB threshold).

85dB for an eight-hour average exposure.

Whispered voice (30dB), normal conversation (60dB), framing saw (82dB), Backhoe (85dB), Bulldozer (100dB), Jackhammer (102dB), grade & scraper (107dB), chain saw (110dB), jet engine at takeoff (140dB), gunshot (140dB).

Yes, you can wear earmuffs that are specifically designed to mount to hard hats and safety helmets.

Expandable foam plugs, canal caps, earmuffs, electronic earmuffs.

Skullerz 8880 Hard Hat Mounted Earmuffs are tested and certified to 26dB Noise Reduction Rating (NRR) when used with Skullerz hard hats and safety helmets.

Over time, extended exposure to loud noises can damage the fibers in ears and cause noise-induced hearing loss.

OSHA requires that employers shall make hearing protectors available to all employees exposed to an 8-hour time-weighted average of 85 decibels or greater at no cost to the employees. Hearing protectors shall be replaced as necessary.

Hearing protection devices, such as earmuffs and earplugs, help reduce excess noise that may cause damage to the inner ear.

(1) Turn the volume down. (2) Walk away from the loud noise. (3) Take breaks from the noise. (4) Avoid loud, noisy activities and places. (5) Use hearing protection.